Once the crystallites are elongated they appear as the.

Grain direction in sheet aluminum.

That has negligible impact on part strength.

Bending with the grain gives a different result than bending against it.

When sheetmetal is bend perpendicular to rolling direction grain rearranges.

The grain direction of the metal also contributes to the amount of springback that occurs in a bending operation.

7075 is very notch sensitive.

The crystalline lattice structures form during the cooling of the metal from its molten state and are held together by thin layers of amorphous solid.

Whereas bending parallel to rolling direction can lead to cracks because of destruction in grain structure.

I m sure that 7075 sheet is made the same as 6061 with grain running lengthwise.

This has to do with the sheet grain direction.

These grains vary in size and in orientation but are usually microscopic and directed from processing conditions.

Strength will be the same in all directions.

The grain direction is in the rolling direction of the sheet as it was being manufactured.

By default in my testing the bounding box aligns itself with the longest straight side.

As a general rule the grain line must run perpendicular to the bend to avoid the potential for cracking or fracture.

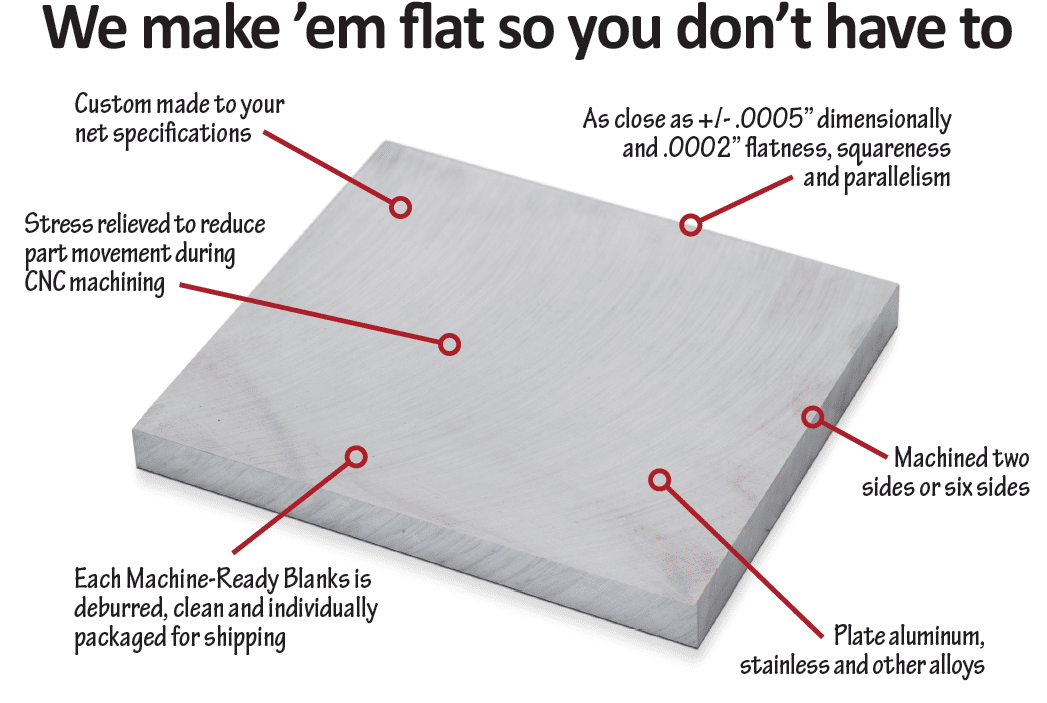

The grain direction is established during the metal rolling process.

A plate s grains run parallel to the rolling direction.

You ll now see that your flat pattern is generated based on one edge oriented parallel to the angled edge and the other obviously perpendicular to that in drawing the rectangle.

You can define a grain direction to use when calculating the bounding box for sheet metal parts.

Where does grain direction come from.

When working with aluminum plate for example you need to pay close attention to whether you are forming with longitudinal or across transverse the grain direction.

Two rollers compressing the hot metal cause the polycrystalline material to elongate in the direction of rolling.

From the flat pattern properties we can select a new edge for the grain direction.

Applying this to metal bending be it plate bending press braking or any other type of metal forming consideration must be given to the grain direction before any process is carried out.

During sheet metal processing rolling operation material grains are arranged in the direction of rolling.